Load cells are an essential part of modern weighing machines. They contribute to quick and accurate results in the present-day weighing equipment. The load cells were not present in the weighing machines in earlier days, but now almost all the scales are digital and come equipped with load cells.

Weighbridges are giant weighing machines used to weigh loaded and unloaded vehicles like trucks. They are also equipped with high-capacity load cells that offer accurate readings every time the weighbridges are used. Let us know more about the importance of load cells for weighbridges.

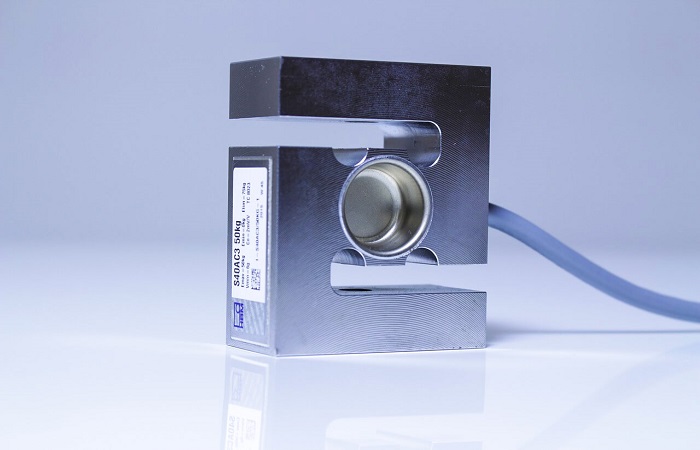

What are load cells

Load cells are the main components in a weighbridge that measures the amount of pressure or force when a vehicle comes on the weighbridge. Load Cells consist of a spring, and strain gauges are mounted on that spring. The spring elements are made of aluminum or steel and are minimally elastic.

The load cell is generally referred to as a transducer, converting the mechanical force into an electrical signal. Normally, the load cell curves slightly when the weight is applied to it.

In the case of compression-mounted load cells that are directly under a weighing device, such as a weighbridge, the load cell is compressed when a load is applied.

The function of a load cell is to produce a signal that is proportional to the pressure applied by the weight of the object. The signal is fed to a weighing indicator which converts it from analog to digital.

When a piece of weighing equipment requires more than one load cell, each of them should measure the same proportion of the total load. Therefore, in a system with four load cells, each must measure a quarter of the load.

So, when a vehicle comes over the weighbridge, the springs are slightly deformed in response to the load of the truck. The deformation of these spring elements is interpreted by the electronic circuit to determine the weight of the load on the weighbridge. The accurate weight of the vehicle is displayed on the digital display.

A weighbridge is a large platform scale used to measure the weight of a vehicle. A truck scale is calibrated by the manufacturer and used to issue tickets for commercial invoicing.

Load cell types in a Weighbridge

- Double-cut beam load cell

- Canister

- Rocker column

Load cells are generally made of stainless steel or alloy steel.

Stainless steel load cell

The load cells made of stainless steel are highly durable but more expensive than those made of alloy. Sometimes, they come with hermetically sealed tape cavities, making them ideal for corrosion and wet applications.

Alloy steel load cell

Suppliers of alloy steel load cells are the most popular today. The cost/performance ratio is better than stainless steel load cells.

If you are looking to buy a weighbridge, then you should check the weighbridge manufacturer and the type of load cell installed in it. Although it is not possible to see the load cell, you should inquire about the type, quality, and capacity of the load cell as well as the weighbridge.

Millennium Mechatronics offers high-quality weighing equipment at affordable prices in Australia. Their product range includes load cells, weighing machines, and accessories for residential and commercial use. They design and manufacture load cells and weighing scales with quality control.

Final Words

Load Cells are the primary components that measure the weight of an object on a weighing scale. The higher the quality of load cells, the more is the accuracy and reliability of the scale. Whether it is a bathroom scale or a giant weighbridge, you should always ask about the loadcell quality and warranty before buying weighing equipment for your home or business.